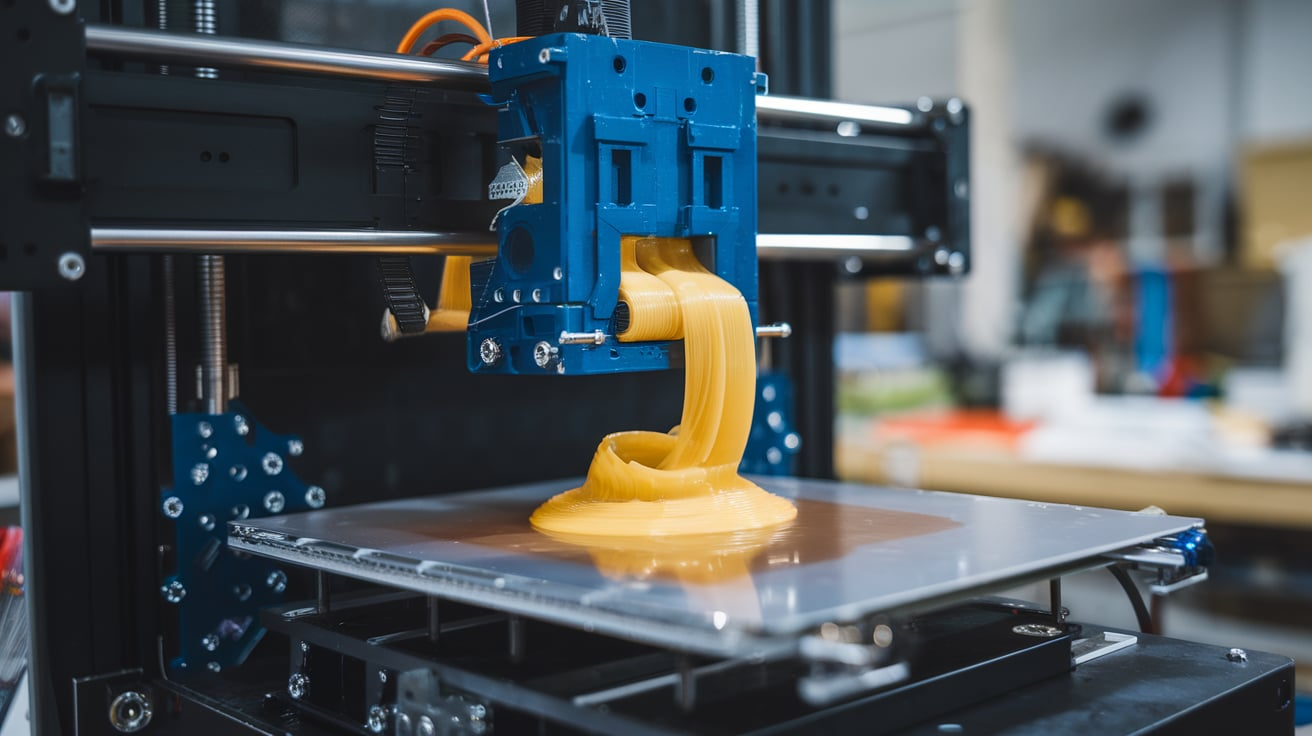

Are you looking for the perfect online extrusion tool? The online extrusion tool is essential for those in industries like manufacturing and 3D printing, helping to shape and modify materials with precision. This tool allows users to customize designs, calculate extrusion rates, and get the ideal settings for specific projects. If you’re new to the world of extrusion or simply looking for a better way to handle your projects, this guide will introduce you to the best online extrusion tools available today.

With the rise of digital tools and software, online extrusion tools have become an invaluable resource. These tools allow users to easily adjust parameters like extrusion rate, temperature, and material type. Whether you’re involved in industrial extrusion or looking for a way to enhance your 3D printing process, an online extrusion tool helps you optimize the quality and efficiency of your designs. These tools can also help you simulate different extrusion scenarios, so you can identify potential issues before production begins. Using the right online extrusion tool can save time, reduce errors, and ultimately improve the success of your projects.

What is an Online Extrusion Tool and How Does It Work?

An online extrusion tool is a software application designed to help with the extrusion process in industries like 3D printing and manufacturing. It allows users to design, simulate, and optimize the extrusion of materials with ease. The tool works by providing real-time data on how materials will behave when they are forced through a mold or die. By adjusting factors like speed, temperature, and pressure, users can control the final outcome of their projects. This tool helps you visualize the results before starting the production, ensuring that the design is flawless. Overall, online extrusion tools improve precision, reduce waste, and streamline production.

Why Every Professional Needs an Online Extrusion Tool for Accurate Results

Every professional involved in material extrusion needs an online extrusion tool to ensure accuracy and efficiency. These tools allow users to control the extrusion process, offering precision that would be difficult to achieve manually. With the ability to adjust parameters like temperature, speed, and pressure, professionals can make sure the material flows smoothly and consistently. This leads to fewer defects in the final product and a faster, more reliable production process. Moreover, online extrusion tools often come with simulation features, helping professionals visualize the results before executing them. By relying on an online extrusion tool, professionals can save time, reduce material waste, and ultimately produce better quality results.

Key Features to Look for in an Online Extrusion Tool

When selecting an online extrusion tool, it’s essential to consider a few key features to ensure you’re getting the best tool for your needs. First, the tool should offer accurate simulation capabilities, allowing you to see how materials will behave before you begin the actual extrusion process. It should also provide customization options, enabling you to adjust parameters such as pressure, speed, and temperature to achieve optimal results. Additionally, user-friendly interfaces and robust support are essential, especially for beginners. Look for tools that integrate well with other software or hardware used in your workflow to increase efficiency. Lastly, compatibility with various materials and the ability to work with complex designs is crucial for professionals aiming to create precise and high-quality products.

Top 5 Online Extrusion Tools for Beginners and Experts in 2025

As the demand for efficient and precise extrusion grows, many online extrusion tools are emerging. Here are five of the best tools to consider in 2025, whether you’re a beginner or an expert. For beginners, Tool X offers a simple interface with step-by-step guidance and easy-to-use features. For more advanced users, Tool Y provides high-level customization, detailed simulations, and powerful analysis options. Tool Z is perfect for professionals working with multiple materials, offering compatibility with a variety of 3D printers and other equipment. Tool A shines with its integration of real-time data, allowing users to monitor their projects throughout the entire process. Lastly, Tool B is ideal for experts looking to scale up their projects, featuring high-end features like cloud-based access and collaboration tools.

How to Use an Online Extrusion Tool for Efficient Project Planning

Using an online extrusion tool for project planning can significantly improve efficiency. The first step is to choose the correct material and set up your project parameters, such as temperature, speed, and pressure. This allows you to simulate how the material will behave under different conditions. Next, review the design in 3D to check for any potential issues, such as incorrect extrusion paths or material inconsistencies. Many online tools offer a visualization feature that lets you see a preview of your extrusion process before starting, saving time and reducing material waste. By using these tools for project planning, you can troubleshoot and refine your designs early in the process, leading to smoother production and reduced costs.

Choosing the Right Online Extrusion Tool: Factors You Should Consider

When selecting an online extrusion tool, there are several key factors to consider. Start by evaluating the tool’s ease of use and the learning curve required. Some tools have simple interfaces suitable for beginners, while others offer more advanced features for experienced users. Consider the types of materials the tool supports, as well as its compatibility with your existing hardware or 3D printers. If you work on large projects or collaborate with teams, look for online extrusion tools that offer cloud-based options or multi-user access. Finally, assess the tool’s customer support and online resources, as these can be helpful when troubleshooting or learning new techniques.

How an Online Extrusion Tool Enhances the 3D Printing Process

An online extrusion tool plays a crucial role in enhancing the 3D printing process. By using an online extrusion tool, you can precisely control the extrusion rate, speed, and temperature to match the specific requirements of your project. This control ensures that materials are extruded consistently and accurately, preventing issues like warping or under-extrusion. Additionally, online extrusion tools allow for real-time adjustments, which can improve the overall quality of the printed product. Whether you’re working with complex geometries or need precise layers, the right online extrusion tool can optimize your 3D printing projects and produce high-quality results every time.

Troubleshooting Common Issues with Online Extrusion Tools

While online extrusion tools are powerful, they may present some challenges. One common issue is inaccurate extrusion rates, which can lead to uneven material flow or poor-quality outputs. To resolve this, check the material settings and ensure that the extrusion rate is properly calibrated. Another issue is temperature fluctuations that may affect the material’s behavior. Always verify that your tool is set to the correct temperature range for the specific material you’re using. Additionally, if the tool is not syncing with your 3D printer, check for software updates or compatibility issues. By troubleshooting these common problems, you can ensure smooth operation and improve the efficiency of your extrusion process.

How to Maximize the Efficiency of Your Online Extrusion Tool

Maximizing the efficiency of your online extrusion tool involves understanding its features and utilizing them to their full potential. First, ensure that you’re regularly updating the software to access the latest tools and improvements. Learn how to adjust key parameters like extrusion rate, material pressure, and temperature to match the requirements of your specific projects. Also, take advantage of simulation features to test your designs before beginning the extrusion process. By identifying potential problems early, you can save time and materials. Finally, regularly clean and maintain your extrusion tool to ensure it operates at peak performance, extending its lifespan and reducing the risk of malfunctions during critical projects.

Online Extrusion Tool vs. Traditional Methods: Which One Should You Choose?

When comparing online extrusion tools with traditional extrusion methods, it’s clear that each has its advantages and disadvantages. Traditional methods often require manual calculations and physical testing, which can be time-consuming and costly. On the other hand, online extrusion tools offer fast simulations and allow for precise control over every parameter, making the process much more efficient. If you need to quickly adjust your designs or work with various materials, online tools are ideal. However, traditional methods may still be necessary for large-scale production or when dealing with unique materials that require a more hands-on approach. Consider your project’s scope and needs to determine which method is best for you.

Understanding the Advantages of Using an Online Extrusion Tool for Complex Projects

Using an online extrusion tool for complex projects offers numerous benefits, especially when dealing with intricate designs or specialized materials. One significant advantage is the ability to simulate different extrusion parameters and see the potential outcomes before actual production begins. This helps identify issues like inconsistent material flow or weak points in the design early in the process. Online tools also allow you to experiment with various material combinations, temperatures, and extrusion rates without committing to expensive prototypes. By leveraging these capabilities, you can optimize your designs for both performance and cost-effectiveness, ensuring the best results for complex extrusion projects.

The Future of Extrusion: How Online Tools Are Changing the Industry

The future of extrusion is being shaped by the continued advancement of online tools. As technology improves, online extrusion tools are becoming more sophisticated, allowing for better material analysis, real-time adjustments, and integration with other manufacturing processes. These tools enable manufacturers to streamline their workflows, reduce waste, and produce higher-quality products more efficiently. With the rise of automation and artificial intelligence, we can expect online extrusion tools to become even more intuitive and capable of handling complex projects with minimal human intervention. As these tools evolve, they are poised to revolutionize the extrusion industry, making it more accessible, cost-effective, and innovative than ever before.

Conclusion:

Using an online extrusion tool can really make your projects easier and more efficient. With these tools, you can adjust everything from speed to temperature to get the best results. Whether you’re a beginner or an expert, online extrusion tools help you create high-quality products and fix any issues before you start working on them. They also save time and money by letting you try out your ideas virtually before making them for real.

The future of extrusion looks bright with these tools becoming more advanced. Soon, these tools will help more people create better and faster products, with fewer mistakes. Whether you are working on simple or complex projects, an online extrusion tool can be the key to getting things done right. So, it’s time to start using these tools to take your work to the next level!

FAQs:

Q: What is an online extrusion tool used for?

A: An online extrusion tool is used to control and manage the process of extrusion in 3D printing and manufacturing. It helps you set parameters like temperature, speed, and pressure to create high-quality products.

Q: Can I use an online extrusion tool for different materials?

A: Yes, many online extrusion tools support different materials, allowing you to choose the best one for your project. You can customize the settings based on the material you’re using.

Q: Are online extrusion tools easy to use?

A: Yes, most online extrusion tools are designed to be user-friendly, with simple controls and features that help you get started quickly, even if you’re new to extrusion.

Q: How do I troubleshoot problems with an online extrusion tool?

A: If you face problems with your online extrusion tool, check the settings for temperature or extrusion rates. Make sure everything is updated and properly calibrated for the material you’re using.

Q: Can an online extrusion tool improve my 3D printing process?

A: Yes, using an online extrusion tool can help improve your 3D printing process by ensuring accurate material flow, reducing waste, and providing better results for your prints.